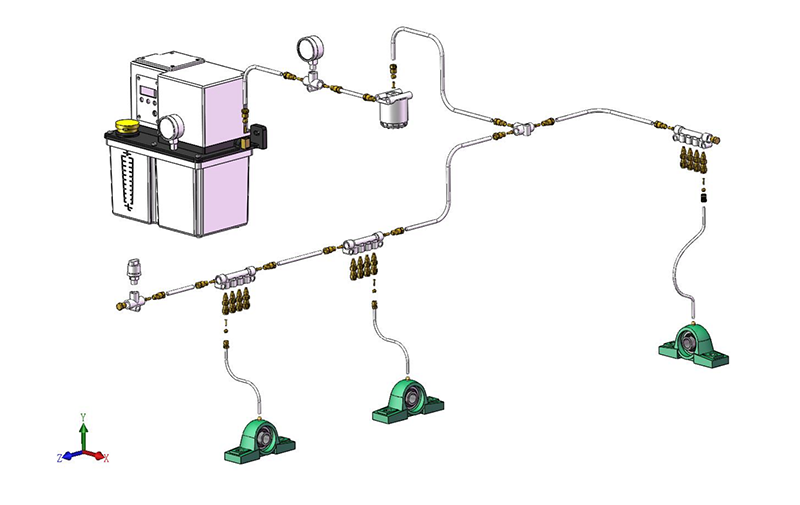

Auto Lubrication Series Progressive Single-line Systems

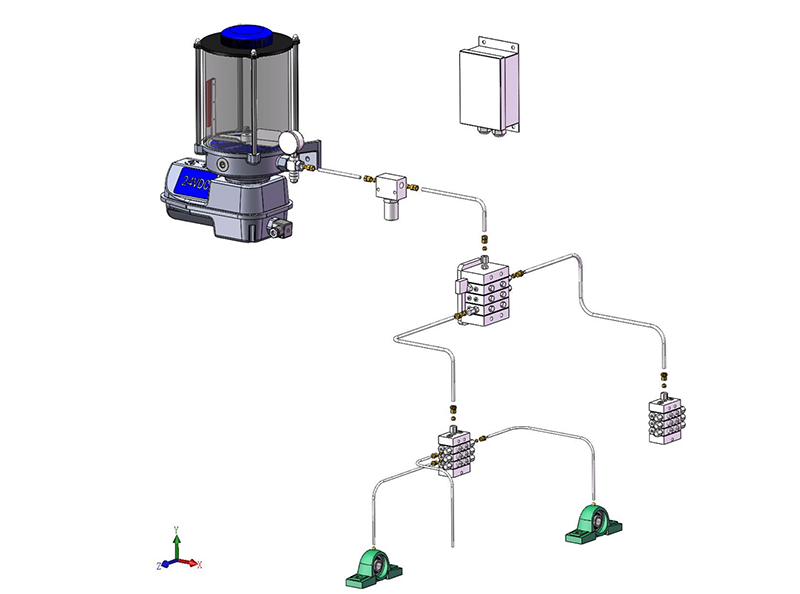

The progressive lubrication systems allow oil or grease (up to NLGI 2) distribution to lubricate the friction points of the machines. The divider blocks of between 3 and 24 outlets guarantee a correct discharge for each point. The system is easy to control and can be monitored by an electrical switch on the main divider.

Ideally suitable for the automatic grease lubrication of all types of industrial machines and as a chassis lubrication pump for trucks, trailers, buses, construction and mechanical handling vehicles.

In conjunction with 1000, 2000,3000 or MVB progressive dividers, more than three hundred greasing points can be automatically centralized from just a single grease pump.

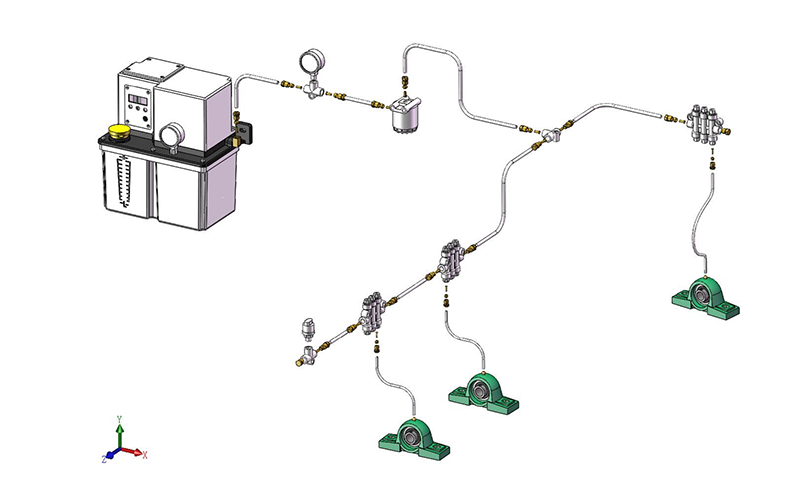

The pumps are designed for intermittent or continuous operation to provide regular pre‐programmed lubrication cycles as required for the various applications.

A direct‐mounted electric geared motor drives an internal rotating cam, which can actuate up to three externally mounted pump elements. Every pumping element has a relief valve to protect the system against over‐pressure.

To have a bigger discharge it is possible to collect the three outlets from the pumping elements together in a single tube.

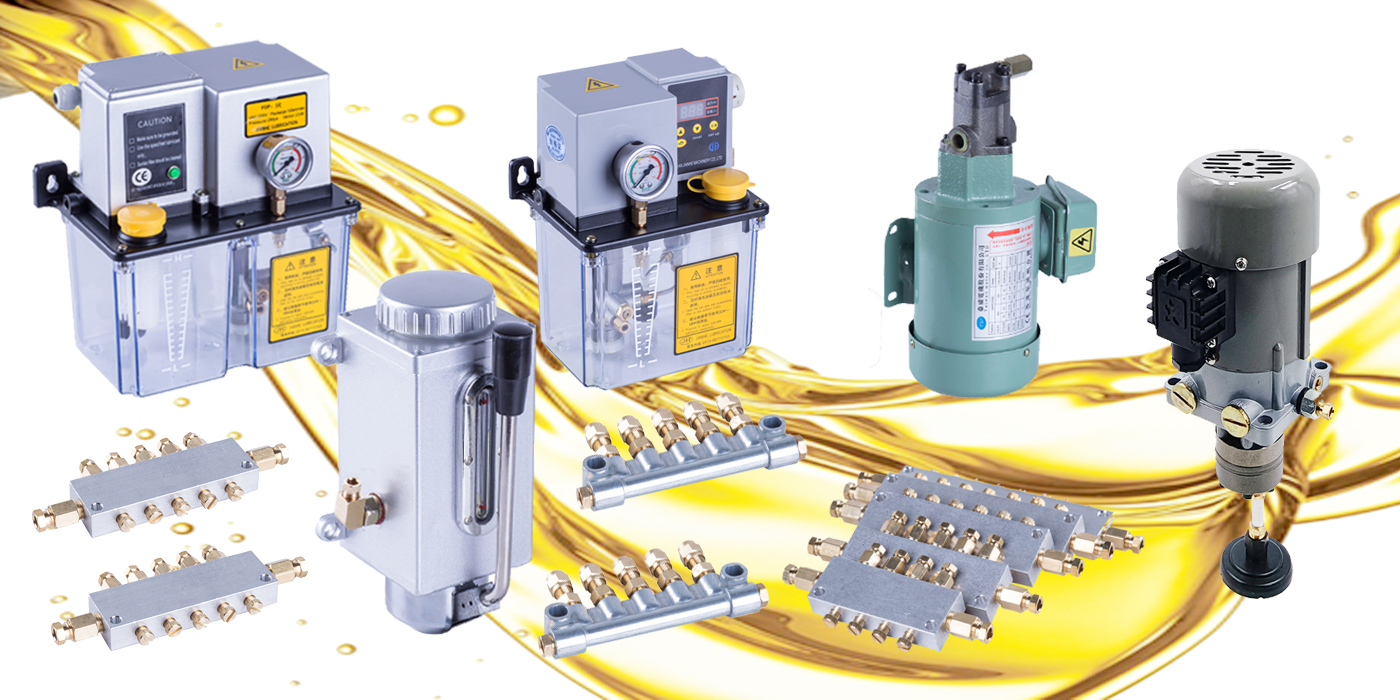

Volumetric Lubrication - Positive Displacement Injector Systems

The volumetric system is based on Positive Displacement Injectors (PDI). A precise, predetermined volume of oil or soft grease is dispensed to each point unaffected by temperature or viscosity of the lubricant. Both electric and pneumatic pumps are available to ensure a discharge up to 500 cc/minute via a range of injectors extending from 15 mm³ to 1000 mm³ per cycle.

Single line lubrication systems are a positive hydraulic method of delivering lubricant, either oil or soft grease under pressure to a group of points from one centrally located pumping unit the pump supplies lubricant to one or more metering valves. The valves are precision measuring devices and deliver an accurate metered volume of lubricant to each point.

Positive displacement injector systems are for low or medium pressure oil or grease lubrication systems. These systems are precise in their lubrication delivery, and some models are adjustable, so a single injector manifold can be used to deliver different amounts of oil or grease to different friction points.

Injectors are alternately activated and deactivated at regular intervals. Oil and fluid grease discharges from the injectors when the system reaches operative pressure.

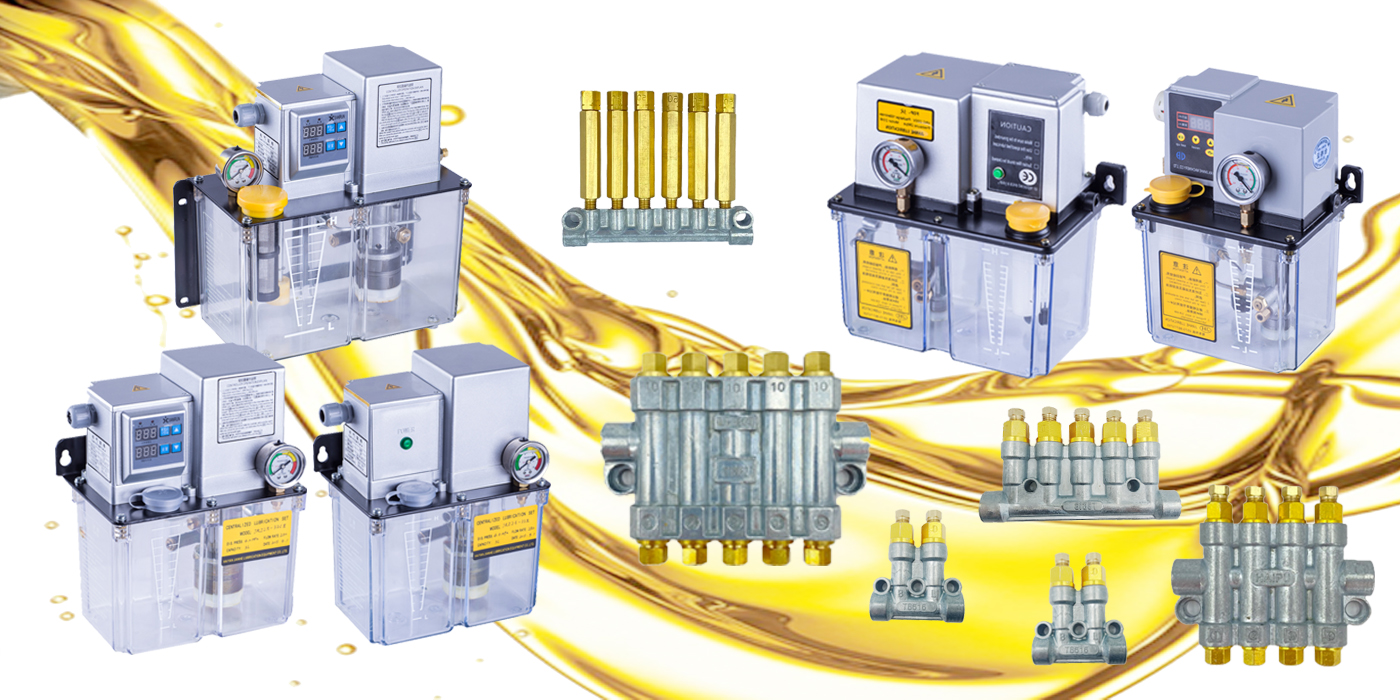

Single Line Resistive Lubrication Systems/Pumps

Less complicated, cheaper and easier to install than any other systems. The single line Resistance System facilitates the supply of small doses of oil by mean of Metering Units. Both electric and manual pumps are available to ensure a discharge of up to 200 cc/minute via range of Metering Units. Oil dosage is proportional to the pump pressure and oil viscosity. Single Line Resistive lubrication systems are low pressure oil lubrication systems for light, medium and heavy machinery requiring up to 100 points of lubrication. Two types of systems (manual and automatic) are available to meet virtually any industrial application.

System structure

1) Manual systems are ideally suited for machinery which can be lubricated by a hand actuated, intermittently fed oil discharge system on an occasional basis.

2) Automatic systems are ideally suited for machinery requiring an uninterrupted discharge of oil either regularly timed or continuous. Automatic systems are actuated by a self-contained timing mechanism or by a mechanical drive mechanism connected to the equipment being lubricated.

Advantages

Single line resistance systems are compact, economical and relatively simple to operate and maintain. The system is ideally suited for machinery or equipment which displays closely configured bearing clusters, or groups.

A precisely controlled discharge of oil is delivered to each point while the machine is in operation. The system provides a clean film of oil between critical bearing surfaces to keep friction and wear to a minimum. Machinery life is extended and production efficiency is maintained.