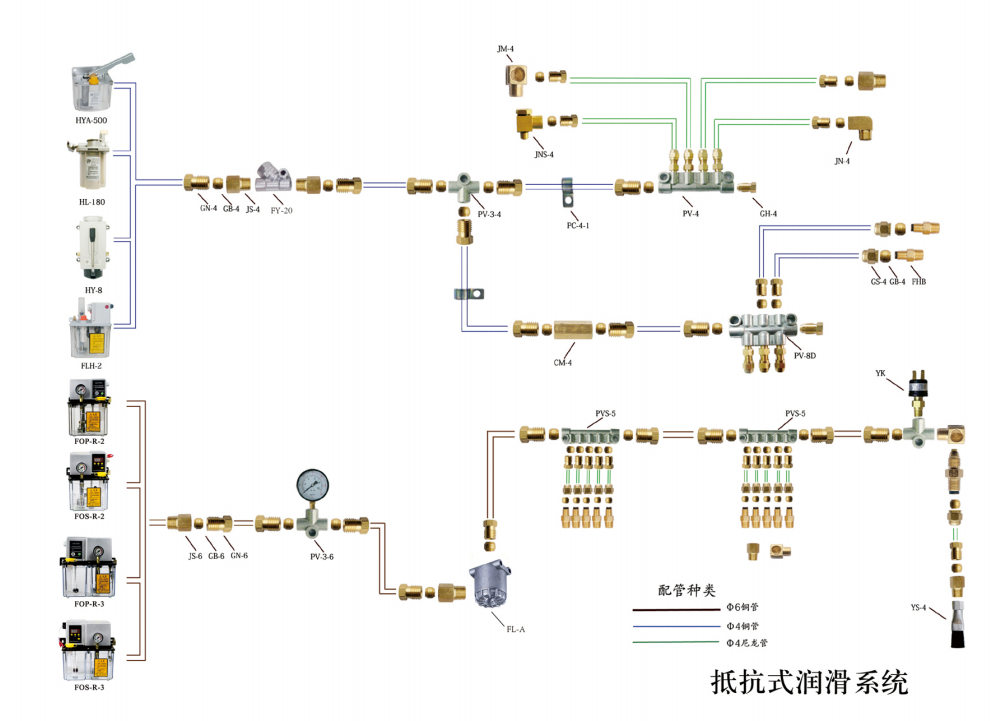

automatic lubrication oil pump are made up of a variety of spare parts and components that are designed to deliver lubricant to the lubrication points of machinery or equipment. Here are some of the common components found in automatic lubrication oil pump :

The pump housing or reservoir is where the lubricating oil or grease is stored. It serves to store the lubricant either indirectly or directly.

The pump motor powers the system to work, generating enough pressure to deliver the lubricant. Depending on the type of pump, it is normal to have a pneumatic or electric motor.

Control System: The control system manages the operation of the pump, including starting, stopping and controlling lubricant flow. It may include control valves, timers, sensors and an electronic control unit (ECU) to regulate the lubrication process.

Distribution System: The distribution system consists of the pipes, hoses or tubing that carry the lubricant from the pump to the lubrication point. It may include fittings, connectors and couplings that link the pump to the lubrication point.

Metering devices: Metering devices are used to regulate the flow of lubricant to individual lubrication points, such as in progressive or dual line lubrication systems. These devices ensure that the correct amount of lubricant is delivered to each lubrication point.

Filters: Filters are used to remove contaminants and impurities from the lubricant before it reaches the lubrication point. They help maintain the quality and cleanliness of the lubricant and protect the system from damage.

PRESSURE RELIEF VALVES: Pressure relief valves are safety devices that prevent excessive pressure in pumps and systems. They open when pressure exceeds a predetermined level, allowing excess lubricant to bypass or return to the reservoir.

Together these make up an automatic lubrication oil pump.

https://www.jianhelube.com/fbsfbp-type-thin-oil-pumps-product/

Post time: Oct-26-2023